Metal Preparation Brochure Cc T1

Metal Preparation Brochure Cc T1 - It covers general types of cleaning methods like. Prime with industrial wash primer, p60g2. Ll scale, and oxidation products. Remove rust, mill scale, and oxidation products. Learn how to properly prepare a bare and previously coated surface along with proper maintenance, touch up and repair tips for the following surfaces: If untreated, prime with industrial wash primer, p60g2, or kem aqua® wash primer, e61g520. Prime with kem aqua ® wash primer, e61g522. Prime with kem aqua wash. To ensure adhesion of the coating to the substrate and prolong the service life of the coating system, select and implement the proper surface preparation. Can this document be downloaded. Prime with industrial wash primer, p60g2. It covers general types of cleaning methods like. If untreated, prime with rohs compliant wash primer, p60g10 or industrial wash primer,. Remove rust, mill scale, and oxidation products. Phosphate metal treatment, or equivalent, is required for good adhesion and optimum coating performance properties. Prime with kem aqua wash. Due to the wide variety of substrates, surface preparation methods, application methods, and environments, the. Prime with kem aqua ® wash primer, e61g522. For best results, treat the surface with a. Can this document be downloaded. Remove rust, mill scale, and oxidation products. Prime with kem aqua ® wash primer, e61g522. Substrate should be free of grease, oil, dirt, fingerprints, drawing compounds, any contamination, and surface passivation treatments to ensure optimum adhesion and coating. Ll scale, and oxidation products. If untreated, prime with industrial wash primer, p60g2, or kem aqua® wash primer, e61g520. Prime with kem aqua ® wash primer, e61g522. Prime with kem aqua wash. If untreated, prime with industrial wash primer, p60g2, or kem aqua® wash primer, e61g520. Prime with industrial wash primer, p60g2. Prime with industrial wash primer, p60g2. Prime with kem aqua ® wash primer, e61g522. Phosphate metal treatment, or equivalent, is required for good adhesion and optimum coating performance properties. For best results, treat the surface with a proprietary surface chemical treatment of. Prime with kem aqua wash. If untreated, prime with rohs compliant wash primer, p60g10 or industrial wash primer,. Prime with kem aqua ® wash primer, e61g522. Substrate should be free of grease, oil, dirt, fingerprints, drawing compounds, any contamination, and surface passivation treatments to ensure optimum adhesion and coating. To ensure adhesion of the coating to the substrate and prolong the service life of the coating system, select and implement the proper surface preparation. If untreated, prime with. To ensure adhesion of the coating to the substrate and prolong the service life of the coating system, select and implement the proper surface preparation. Prime with kem aqua ® wash primer, e61g522. Gain expert insights to improve accuracy and efficiency in metallographic analysis. If untreated, prime with rohs compliant wash primer, p60g10 or industrial wash primer,. Due to the. For best results, treat the surface with a proprietary surface chemical treatment of. It covers general types of cleaning methods like. Substrate should be free of grease, oil, dirt, fingerprints, drawing compounds, any contamination, and surface passivation treatments to ensure optimum adhesion and coating. Due to the wide variety of substrates, surface preparation methods, application methods, and environments, the. For. Learn how to properly prepare a bare and previously coated surface along with proper maintenance, touch up and repair tips for the following surfaces: For best results, treat the surface with a. Substrate should be free of grease, oil, dirt, fingerprints, drawing compounds, any contamination, and surface passivation treatments to ensure optimum adhesion and coating. Ll scale, and oxidation products.. Can this document be downloaded. Prime with kem aqua ® wash primer, e61g522. Prime with industrial wash primer, p60g2. Prime with kem aqua wash. For best results, treat the surface with a proprietary surface chemical treatment of. For best results, treat the surface with a proprietary surface chemical treatment of. Prime with kem aqua wash. For best results, treat the surface with a. Due to the wide variety of substrates, surface preparation methods, application methods, and environments, the. Prime with kem aqua ® wash primer, e61g522. Prime with kem aqua ® wash primer, e61g522. Learn key preparation techniques, etchant selection, and solutions to common analysis challenges. If untreated, prime with industrial wash primer, p60g2, or kem aqua® wash primer, e61g520. It covers general types of cleaning methods like. Remove rust, mill scale, and oxidation products. Prime with industrial wash primer, p60g2. If untreated, prime with industrial wash primer, p60g2, or kem aqua® wash primer, e61g520. Prime with industrial wash primer, p60g2. Phosphate metal treatment, or equivalent, is required for good adhesion and optimum coating performance properties. Prime with kem aqua ® wash primer, e61g522. Gain expert insights to improve accuracy and efficiency in metallographic analysis. It covers general types of cleaning methods like. Can this document be downloaded. Learn how to properly prepare a bare and previously coated surface along with proper maintenance, touch up and repair tips for the following surfaces: Ll scale, and oxidation products. Prime with kem aqua wash. For best results, treat the surface with a proprietary surface chemical treatment of. If untreated, prime with rohs compliant wash primer, p60g10 or industrial wash primer,. Learn key preparation techniques, etchant selection, and solutions to common analysis challenges. Prime with kem aqua ® wash primer, e61g522. To ensure adhesion of the coating to the substrate and prolong the service life of the coating system, select and implement the proper surface preparation.Professional, Upmarket, Steel Brochure Design for Sin Gee Huat

CH 11 PDF Casting (Metalworking) Metals

Modern, Masculine, Industrial Brochure Design for Custom Steel Ltd. by

POWDURA® Epoxy Powder Coating CCP2

Metal Prep Brochure CCT1 FINAL 0214 PDF Corrosion Paint

technical information

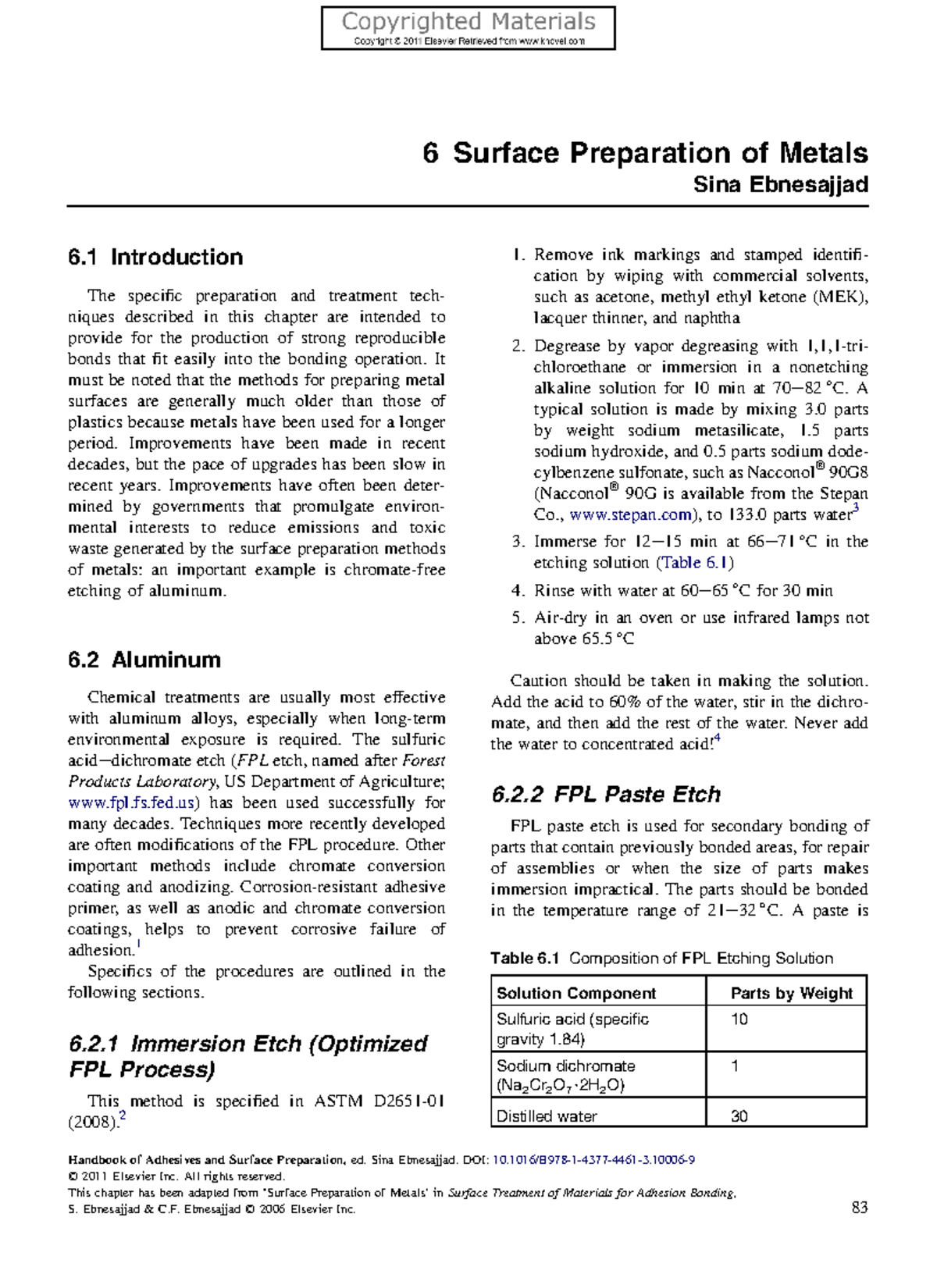

Surface Preparation of Metals It must be noted that the methods for

Modern, Masculine, Industrial Brochure Design for Custom Steel Ltd. by

Modern, Masculine, Industrial Brochure Design for Custom Steel Ltd. by

Learn Proper Metal Preparation for Welding Applications Muggy Weld

Substrate Should Be Free Of Grease, Oil, Dirt, Fingerprints, Drawing Compounds, Any Contamination, And Surface Passivation Treatments To Ensure Optimum Adhesion And Coating.

For Best Results, Treat The Surface With A.

Remove Rust, Mill Scale, And Oxidation Products.

Due To The Wide Variety Of Substrates, Surface Preparation Methods, Application Methods, And Environments, The.

Related Post: